Future should start with your imagination.

Just suppose that the design of buildings and façades were constrained only by the limits of your imagination.

Your ideas. Your intuition.

Your vision, straight out of your own mind.

Various solutions have been put forward in recent years, but none has made a significant impact on the construction industry.

Why?

Because the narrow perspectives and predefined forms of conventional façade systems and planning methods still rein in an architect’s vision.

So we had to seek out a new method, a new system for complex façade constructions that was free from all design constraints.

Lithium Designers GmbH had developed a file to manufacturing concept based on a parametric approach and utilized the potentials of additive manufacturing.

This parametric engineering approach, giving planners and designers around the world the freedom to push creative boundaries further than ever before.

So what if ...

- Our vision is limited by the technical possibilities of current façade systems?

- There is room for improvement in the performance of previous systems in terms of load bearing and material usage?

- Free-form façades are currently highly technical, time consuming, and expensive?

- Planning and engineering such façades using conventional software and methods is highly inefficient if not virtually impossible?

- Sustainability and the efficient use of resources are key aspects of our philosophy?

Shouldn‘t

we just ...

- Tear up the old rules and start thinking in a radically new way?

- Use new innovative digital engineering and production technologies that allow greater design freedom?

- Realize a façade system that leverages topology optimization to adapt to specific needs?

- Switch to more environmentally friendly and resource-efficient production methods?

- Implement the form-follows-function principle consistently and sustainably?

exyz

To maximize design freedom, we had to come up with a system that was free of all constraints.

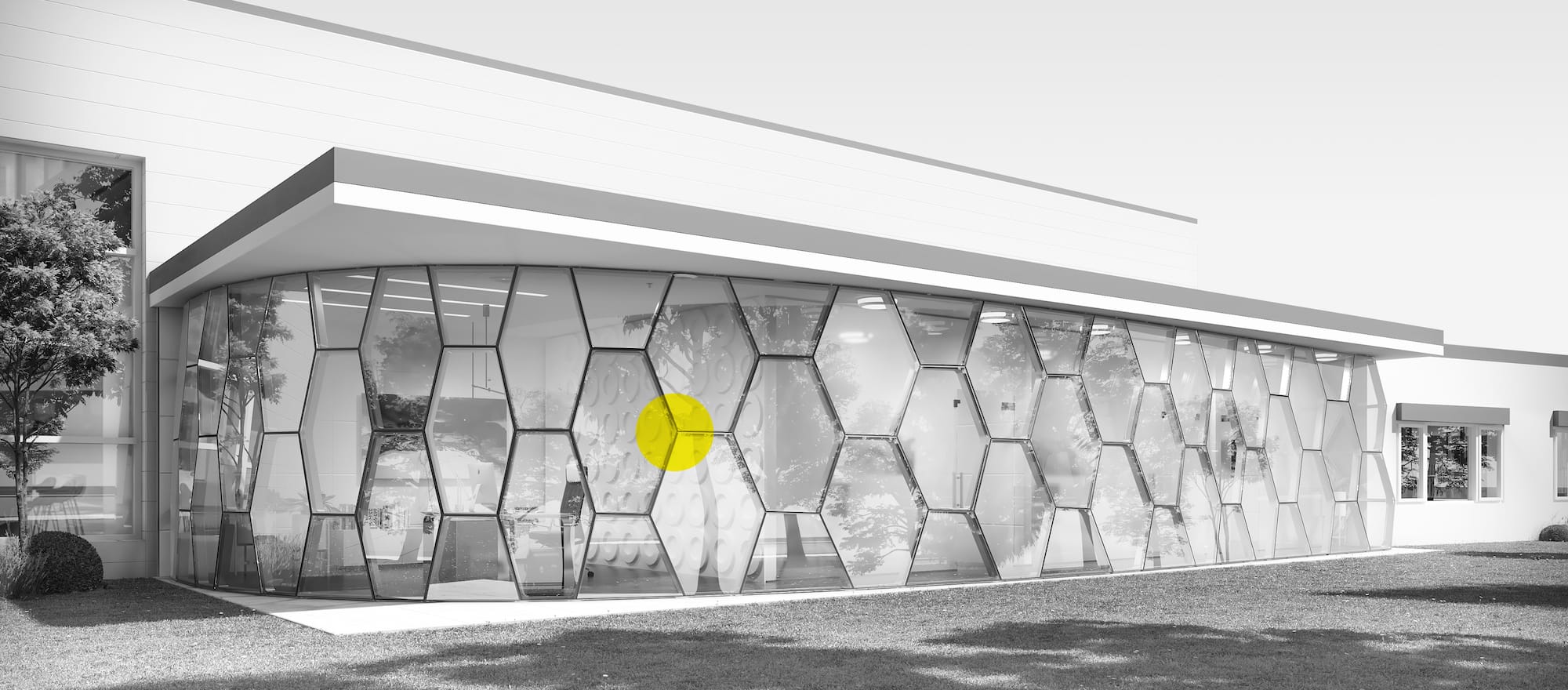

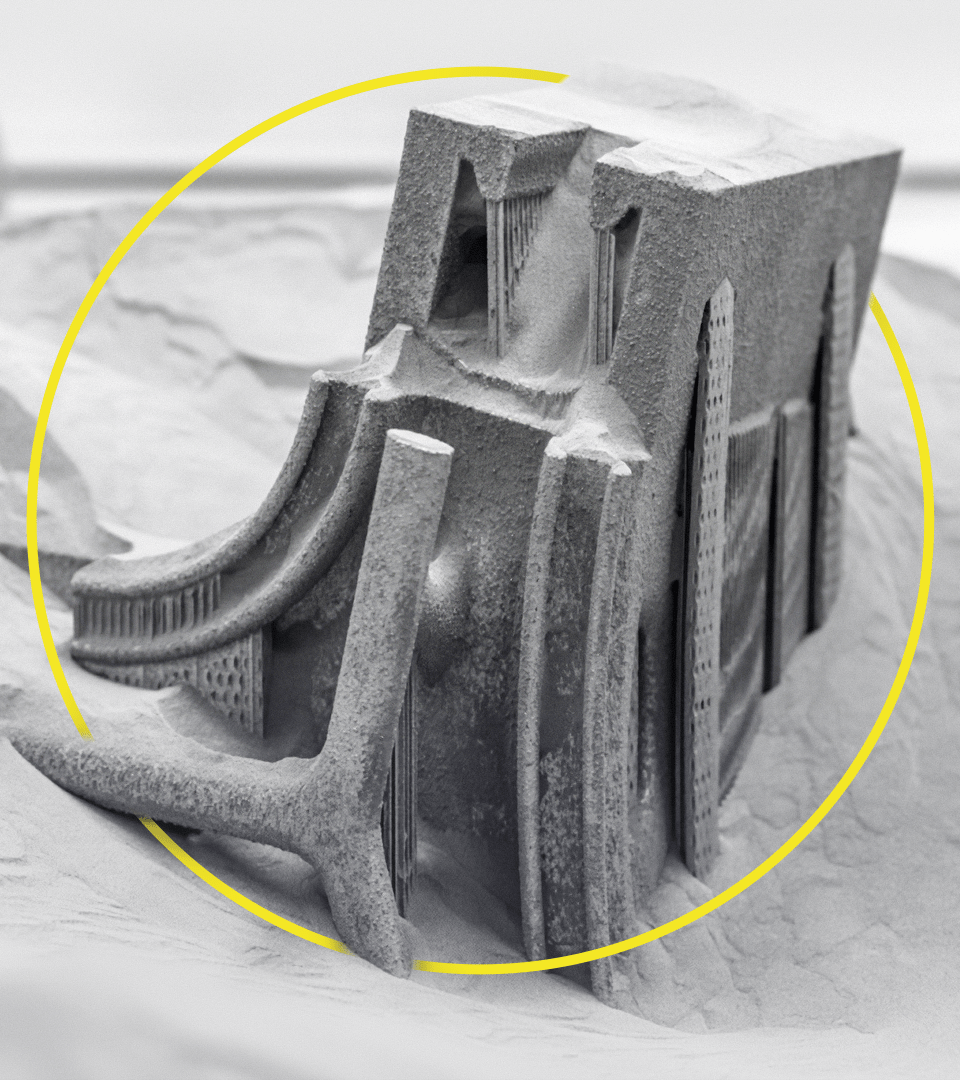

exyz is a façade system that has been designed independently of predefined base modules so that architects are no longer bound by limitations. Supported and compatible with "N-AM_Li3", the world's first certified topology optimized 3D-printed facade node, developed by Lithium Designers GmbH, to accommodate all possible geometric conditions of building envelopes and ensure smooth transition between the profiles.

Li3M software, developed by Lithium Designers, fully supports and extends the exyz facade system. It is a planning tool that generates and verifies the production information of all facade components. Thus, the effort in the planning process can be drastically reduced.

exyz façades

exyz brings together all aspects of a project from design through manufacturing and assembly. All associated parts, such as profiles, seals, and nodes, are generated and checked.

For the first time, complex façades and building envelopes can be realized using a standardized aluminum façade system in combination with 3D printed façade nodes.

exyz façades

exyz combines a method, a system, a piece of software, and a product all rolled into one. The planning method Li3_Methode, the software Li3M and the 3D printed façade node N-AM_Li3 were created by the architecture and engineering firm Lithium Designers GmbH. The exclusive rights to produce the node to the highest quality standards, and to develop the profile system, are held by H+B Hightech GmbH.

And because we wanted to be the first to prove our concept, we can now proudly present HivE, a design of Lithium Designers GmbH.

By the way, N-AM_Li3 façade node is the world’s first 3D-printed façade node to obtain project-related certification (Zulassung im Einzelfall) for use in a German construction project.